How we can save you money

We offer a range of technologies which improve process performance, reduce energy consumption and ease maintenance. Typical systems save between 10% and 25% of energy costs.

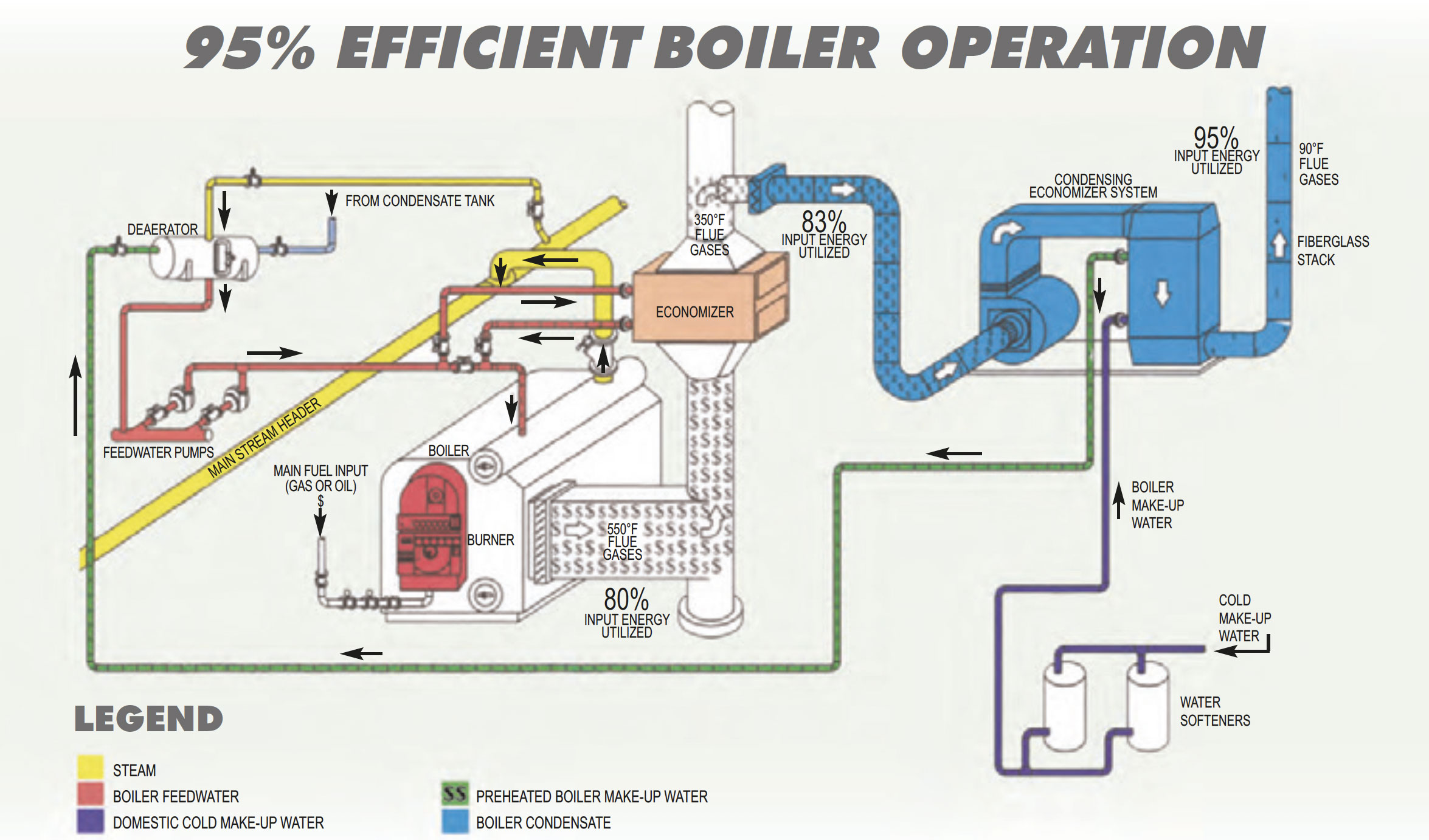

Condensing Heat Recovery

Recovering waste energy, offsetting the use of carbon fuels and reducing CO2 emissions.

- Recovering most of the remaining energy in your exhaust stack to use instead of burning more fuel.

- Generating water from the air that can be used in the boiler or on site.

- Reducing operational costs and improving the bottom line

Modular Construction

The modular construction of the Condex system means

that multiple heat exchangers can be contained in one unit

providing optimum heat recovery and delivery to suit your site.

Maximum recovery, minimum fuss.

Innovative Solutions

High energy recovery from the existing stack means low

temperatures and different materials for our stacks, this one is made

from fibreglass. Innovative solutions driving great projects.

Optimised for Energy Efficiency

Getting every last kWh of energy from your fuel is where the Condex

condensing economizer

design starts. Converting both latent and sensible energy from the

process or boiler exhaust provides large amounts of energy that

can be used in the boiler house or across your site to offset

regular fuel costs.

Engineered for excellence

Condensing exhaust gasses recovers the large amount of latent heat trapped in the exhaust gas as it exits the

boiler or process and it is the release of this energy

that provides such high levels of energy reduction.

Designed to save a fortune

Each Condex system is designed and configured

specifically for the site it works on, matching energy

sources with site requirements to achieve the optimum in energy reduction and

efficiency. offsetting the use of carbon fuels and reducing CO2 and NOx

The Technology Explained

Energy Recovery

Energy Recovery

The hot water, generated from recovering both the latent and

sensible heat in the exhaust, is then used to pre-heat hot water

users on site. The simplest systems can use this heat to preheat

boiler make-up water, offset steam use to the deareator

and increase boiler feed water temperatures and that’s before

any other users are considered outside the boiler house.

The Process

Condex techHot exhaust gas is sucked from the existing site

flue or flues and into the condensing heat exchanger. Cooler

water in one or more streams is then passed through the

heat exchanger tubes transferring heat to the water and

removing heat from the exhaust.

The Condex design of economiser combines both sensible and latent heat recovery making it hugely more efficient

than most economisers. Most economisers are

designed to only recover the sensible heat

which generally only equates to between 4

and 6 percent of the energy consumed.

The Condex design however enables

the collection of energy below the

dew point. This means that all the

latent energy released during the

condensing phase of cooling is also captured raising the potential energy recovered to over

10 percent and often to between 15 and 20 percent of the total energy consumed. A 20

percent energy saving to your fuel bill will really give you something to smile about.

Green House Gasses (GHG’s) are also reduced in large proportion, in part due to the

increase in energy efficiency, but also due to the condensing nature of the economiser,

reducing both CO2 and NOx.

Engineering the Condex condensing economiser to be custom built and ready for shipping,

provides for simple installation leaving only pipework, ducting and local electrical connections to be made once on site..